K40 laser cutter

Your new laser cutter may attempt to kill you in a number of way… - The k40 laser resource / r/lasercutting / K40laser.se / Laser Gods

- Never fire the laser with the cover open.

- Never operate the laser without the water pump functioning, and proper ventilation.

- Never look at the laser directly. Reflections from the laser can permanently blind you. Even reflections off of a wall or material being cut can be incredibly dangerous.

- Never leave the operating laser unattended.

- Have a fire extinguisher on hand, and be able to kill power to the unit immediately in case of emergency.

- Have a properly maintained CO2 fire extinguisher close at hand

- Keep a spray bottle of water to hand to supress small flames that may char your material (and which might grow into a major fire)

During operation the tube also produces non-laser light in other frequencies including ultra-violet which can shine out from the tube in many directions and also reflect off the laser mirrors.

Hardware

Fred Gift

A 3020 model

- M2Nano - Lihuiyu Studio Labs

- Firmware ver 2019.01.12

- Model 6C6879-LASER-M2:9

- point laser

- lentille 12mm Ø

CO2 Laser

![]() - [Approx 20kV arc are powering the laser]

- [Approx 20kV arc are powering the laser]

Before doing anything, remove all power cords and let the machine sit at least 30min before even thinking about touching something close to the power supply.

Customisation

- K40/Chinese CO2 laser cutter/engraver buyer’s guide (Teaching Tech)

- Découpe laser CO2 K40 - Améliorations / hacking de la machine - propose plusieurs amélioration avec leur difficulté et leur pertinance

Analog Control

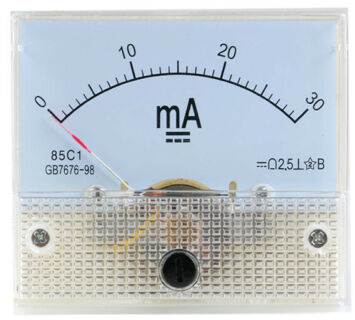

Buttons are just a digital version of the potentiometer, so it works good. Easy to set the power. But you need a mA-meter to keep a eye on power output. 100% on the panel is 140-150% on the tube – and you will kill it quick.

With Amperemetre installed - 26% => 14mA

In order not to shorten the life of your laser you need to keep the current below c. 15mA (for A 30-35W tube).

Convert to Analog

![]()

Beware of proper insulation: Caution! If this wires comes loose it may create sparks, arcing or even fire due to the increased resistance if the connector isnt properly fastened, so take care to make sure both are properly crimped and fastened!

keep your power at safe levels - Adding a mA-meter to your machine is one of the most important modifications you can do on this machine.

- should I change the buttons? No, keep it. If you like it it´s really no reason to change it.

- K40 Laser Amp Meter Installation Miliampmeter - show full build

- K40 laser Amp Meter Install - focus on connection

Current limiting on the laser is done by pulsing (PWM) the power supply,

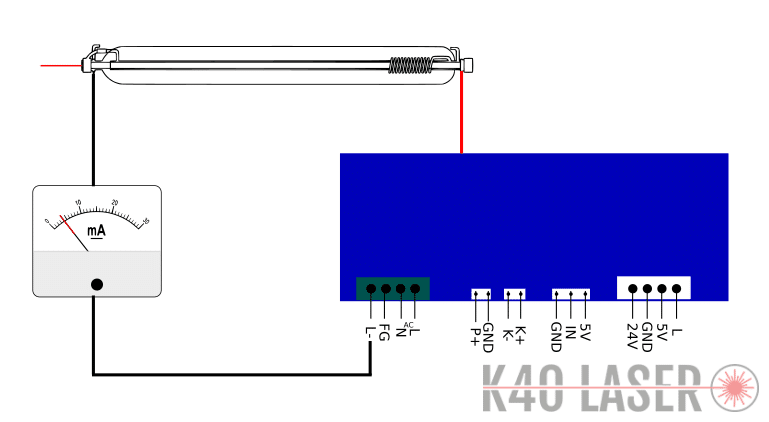

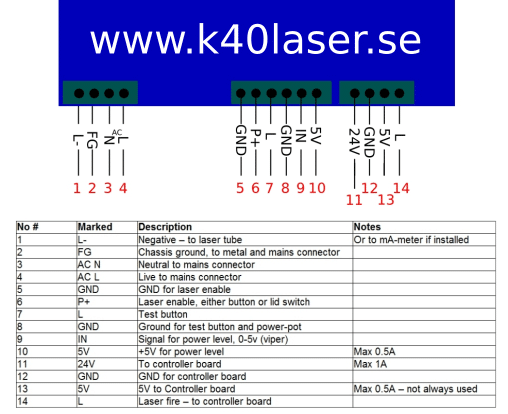

- Laser on and off is controlled by the control board, and it does this the L-pin furthest to the right on the power supply. PIN14 in the picture below. There is more L-pins but these are connected to the test-buttons only. Only jumper cable you should have is the one between P+ and gnd, if you dont have a flow sensor. (pin 5&6 in pic below)

Air assist 🌬️💨

Usual misconception about air assist

The picture below was one of few heads on the market. And it was really bad causing the head acting like a vacuum cleaner, pushing air out in the bottom and sucking smoke in at the top creating optic damages and a lot of cleaning.

Prefer blowing directly on the base.

see also

- Everything You Need to Know About the K40 Chinese Laser Cutter

- K40 Laser control panel best upgrade under $10.

- 2019 K40 laser upgrades, Manual Z axis build.

- K40 Laser Cutter & Engraver - What Do You Really Need To Get Started?

- K40 12x24 Bed Build - Laser tear down and putting the parts together

- OMTECH K40 Plus - Un bon investissement ?

Cooling 💦

The k40’s laser tube is liquid-cooled. Never operate the laser, even for an instant, without active liquid cooling.

It is important that you keep your laser tube below 25°C during use (generally recommended between 15°C and 20°C),

The water will gradually warm up as the laser is operated. When it starts to get warm, either stop using it for a while, or cycle in cooler water.

- Enough cooling to keep your cooling water bucket under 20°C and enough pumping to keep about one liter of water per minute flowing through your laser tube.

- Avoid frozen water => Doing this flirts with causing thermal expansion/contraction cracks in the glass.

- The K40 has to get rid of 160W to 200W of waste heat

- Move about liter of water per minute through the K40 tube, and cool it to between 18°C and 20°C in the cooling tank.

- Always make sure your return hose end goes under the water level in the coolant bucket. This creates a siphon effect which makes your pump work much better.

- Keep in mind that you have to cool the water in your bucket, too, as well as running the water through the laser. Use the largest practical cooling water tank. Most people seem to use 18 to 20 litters and that works well.

It is also essential that the water you use is non-conducting. The easiest way to achieve this is to use deionised water, (we get ours in 5 litre bottles from our local LIDL store at c. 0.70€ per bottle)

It is also essential that the water you use is non-conducting. The easiest way to achieve this is to use deionised water, (we get ours in 5 litre bottles from our local LIDL store at c. 0.70€ per bottle)

- Anti-freeze is problematic. These can easily cause problems with conductivity.

- Algae growth is a problem, as it interferes with water flow directly, deposits on the glass, prevents heat transfer, and on and on.

- Tetra AlgaeControl has been tested to not make your water more conductive.

- Tetra’s AlguMin has been reported to work well.

- Bleach (Chlore) is not recommended.

Make sure that the outlet of the water cooling tube (the circled bit) is pointing up to let the air escape (raise the machine):

- Cooling Liquid in a K40 Laser / What i use

- adding raditor coolant (Glycol 20%) ?

Thermal Sensor

- Connecting the temperature sensor to the M3 nano board?

- The two button cells in the thermometer module which came with my K40 are in parallel. It turns on with just one cell. So, it’s 1.5V.

- Anyhow, some quick googling suggests an LR44 cell has a capacity of 150 mAh. So, 300 mAh for two of them. One AAA cell got 1200 mAh (4x) and an AA cell about twice as much (8x). Either one would last for something like 8+ years.

Tube 🔴

- Durée de vie typique et facteurs d’influence des tubes laser CO2

- Identifying a Defective CO2 Laser Tube by Plasma Color - CO2 laser tubes contain a gas mixture that depletes over time. When the tube is active, you’ll see a purple plasma beam inside. The stronger the color, the more powerful the tube. If the plasma shifts to a pale pink or even white, it’s a clear sign of a defective laser tube.

Focus 🔍

- Find Laser Focal Length Under 2 Minutes

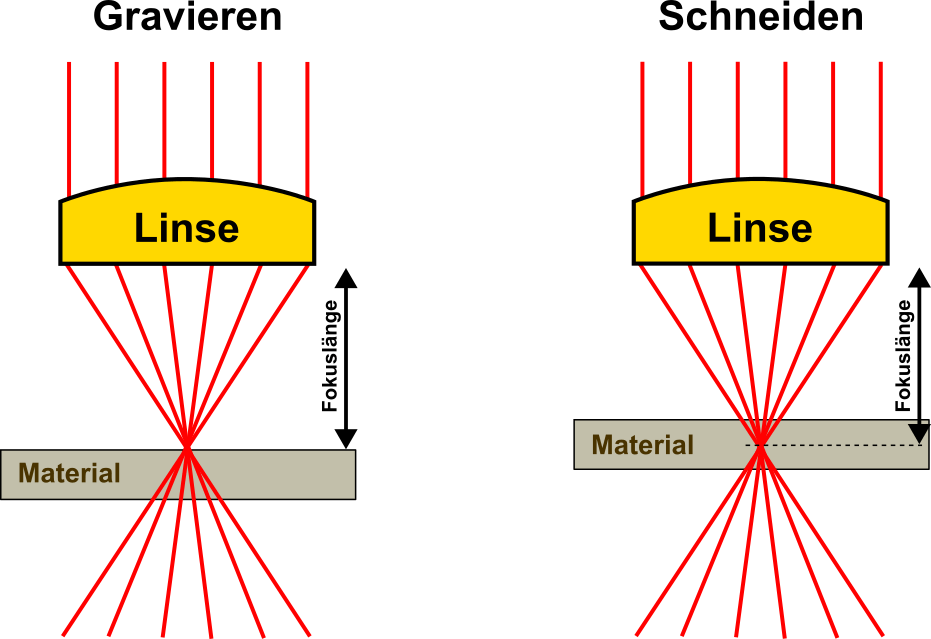

- focal 2” / 50.8mm - for engrafing

- focal 2.5” / 64.5mm - cutting up to 12mm thickness

- focal 4” / 101.6mm - cutting up to 25mm thickness

- Tutorial: How to find focus of laser lens?? CO2 Laser Machine Focal Length - for fixed head height:

- make a ramp

- cut a line over it

- move the laser head on top over the thinnest path

- measure the distancde from the head to the ramp at this place.

- that the distance you want for best focus

- Adjusting Laser Focus – 3 Simple Methods

- Upgrading omtech 60W tube to 100W

- laser led to help alignment

- measure laser power

Cleaning

Mirror Alignment

Using tape is a good solution => but don’t burn it on mirror, the fume from the glue are messing the mirror below. Glue it aside, cf K40 beam alignment target

MeerK40t has a pulse panel to generate consistent laser pulse (rather than the test button on K40 panel)

The smaller, the better. Lower laser power as much as possible to avoid big burn spot.

Do mirror in order, starting from laser beam to cutting plate.

Then for each mirror:

- slide the mirror (if possible) so that the incoming beam fall in the center of the mirror being modified.

- Note: Do not target the center of the mirror from the beam (except maybe for first mirror), but move the mirror itself for centering the incoming beam.

- Align the reflected beam so that it become parrallel in 3D (Horizontal and vertical alignement) to the mechanical axis that it should match, to do that:

- observed the position of the impact off the beam on a close position

- do the same on far away position

The point should match as closely as possible, if not apply the following algorithm to modify the beam alignment (using the relevant mirror screw):

- 1 x screw is fixed: you can think of the middle screw as the pivot point, only there to give some space for pivoting the mirror on the 2 others axis, then:

- 1 x screw is for horizontal alignment

- 1 x screw for vertical alignemnt

Keep the screw as decoupled as above, so that once vertical aligment is reached, moving only one screw is necessary for horizontal alignement.

Once done, use hot glue on mirror screw to secure position.

see also

- combined tube nonmetal co2 laser machine mirror alignment guide - alignment in 33 easy step… 😀

- 3 mirrors

- Main Mirror Replacement

K40 Big Ghosting issue 🛠️

Maybe

- a combination of mirror missalignment

- make sure mirror are clean

- bent brackets

- lack of QC

Grid Adjust

Squareness

Rotary Axis

Software

With a K40, you can set the power of the laser from the front panel, but the controller board is only able to turn the laser on and off.

Fortunately the controller can turn the laser on and off very fast indeed. In fact it can do this 1,000x per inch (or c. 400 per cm) which is enough to turn it on and off several times in the width of the laser beam itself!!

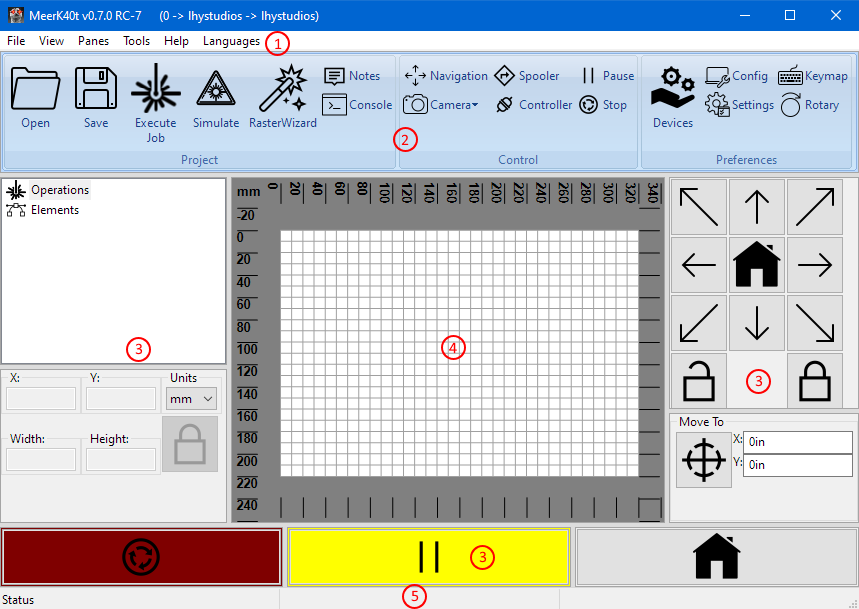

MeerK40t

A replacement for both the software supplied with the K40 and the K40 Whisperer software. It is designed specifically to drive the popular K40 class of (chinese built) laser machines which have an Lhymicro controller board. In the meantime Meerk40 is able to drive other controller boards (e.g. Gerbil based boards, Fibre Lasers and others), and aspires to support even more in the future. - wiki

USB setup

$ lsusb

$ sudo nano /etc/udev/rules.d/99-k40.rules

SUBSYSTEM=="usb", ATTRS{idVendor}=="1a86", MODE="0666"

SUBSYSTEM=="usb", ATTRS{idVendor}=="10c4", MODE="0666"

#

$ sudo udevadm control --reload-rules

$ sudo udevadm trigger

# Unplug and re-plug the USB cableIssue

Tutorials

OpenBuilds

K40 Whisperer

A free open source program alternative to the Laser Draw (LaserDRW) program that comes with the cheap Chinese laser cutters available on E-Bay and Amazon. K40 Whisperer reads SVG and DXF files, interprets the data and sends commands to the K40 controller to move the laser head and control the laser accordingly. K40 Whisperer does not require a USB key (dongle) to function.

VisiCut

use LibLaserCut, a platform independant library for Lasercutters.

Tutos

- Formation débutant sur les découpeurs laser CO2 !

- La découpeuse laser K40 - Découverte (Barbatronic)

- Making an Edge Lit Sign with a K40 Laser Engraver

- Acrylic condensation (RDWorks) - and can catch fire - wary of honeycomb support fume extractor

Other technics

- Powder Coating With Lasers..Kinda - A New Way To Fill Your Engraving With Vibrant Color

Source

- amazon

- VEVOR deconseillé commme vendeur

see also

- Diode lasers vs. Co2 laser tubes. Advantages and disadvantages

- diodes: no single diode can create more than 10 watt optical power / Have a long lifespan (if the diode does not work anything really happens to it).

- Homemade CO2 Laser Tube / Part2

- EFR CO2 laser tube factory ,60W to 220W power

- DIY Laser cutter - part 2